Use for efficient substances

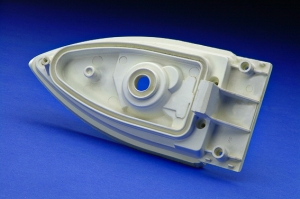

Telephone boxes, kitchen sinks and car hoods: SMC is used wherever high mechanical strength and rigidity are required. SMC is a molding compound based on glass fiber-reinforced UP resins and is therefore also called resin mat or prepreg. Its durability is exceptional, as the plastic retains its strength for decades, even in outdoor applications.

The excellent electrical properties of the material have been used industrially since the 1960s, for example in cable distribution cabinets. SMC got its start in the automotive industry in the 70s. The best example: the bumpers of the Renault R5 were made of SMC. SMC offers a wide range of design options, a high surface quality and can be processed using both warm and hot pressing methods. We supply this exceptionally versatile construction material as a semi-finished product in rolls, making it the ideal material for large-area molded parts.

Application Focus

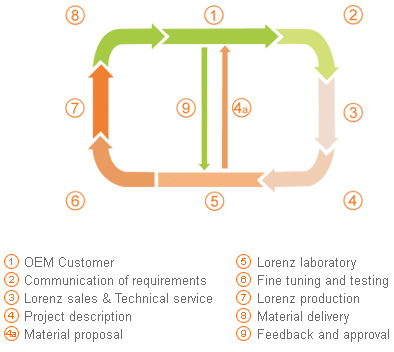

SMC Compounding

SMC: Sheet Moulding Compound

Also called resin mat or prepreg in Germany.

Is a molding compound based on glass fiber reinforced UP resins. It is sold in rolls wound onto a core with a weight of approx. 0.3 - 0.5 tons and belongs to the Thermosets.

According to DIN 16913, 5 SMC types are standardized. In addition, there are a large number of non-standardized SMC formulations, tailored to the respective application.

The SMCs are processable delivered and processed into molded parts under pressure and temperature in steel tools.

The industrial use of SMC began in the first half of the 1960s. The generally excellent electrical properties of the material were utilized in applications such as cable distribution cabinets, linear luminaires and various parts for the electrical insulation sector.

At the beginning of the 1970s, SMC found its way into the automotive industry, for example the bumper for the Renault R5, which was one of the largest applications in Europe. Together with the R11, R14 models and other parts, Renault processed a maximum of 50-60 tons per day.

Overview of applications from SMC :

Car and truck sector:

Bumpers, oil pans, cylinder head covers, hoods, trunk lids, engine compartment encapsulation, stone chip protection

General:

House junction boxes, cable distribution cabinets, interior cladding, window frames, circuit breakers, circuit breaker switches, exterior cladding, power contactors, insulation panels, linear luminaires, telephone boxes, recycling container bases, industrial vacuum cleaner housings...